Description

VTA T9401 expands the blow off sound options for your VW or Audi!

WORLDWIDE PCT PATENTS PENDING

PROTECTED BY CHINA UTILITY MODEL PATENTS; CN206054094U & 206129406

The VTA is a performance blow-off valve solution for Audi or VW vehicles with an electronic factory diverter valve.

Choose Your Sound…

With the removable extended trumpet, you can configure the T9401 to give you either a classic “whoosh”, or the loudest, most unique whistle sound you’ve ever heard on a Euro vehicle!

Customize the sound!

The T9401 also features adjustable spring pre-load so you can fine tune when it blows off, and for how long. A softer pre-load allows the valve to blow off for longer and at lower engine loads. If you prefer to hear it only at higher engine loads you can use a firmer pre-load.

Low-Profile, Easy Installation

Using our integrated solenoid design stacked in an “over/under” configuration, the super-low profile allows clean and simple fitment (even if your aftermarket intake is using up all the space!)

Is This the Right Valve for Me?

If you haven’t already checked that your vehicle is on the fitment list, do that first. (SELECT BY CAR ABOVE)

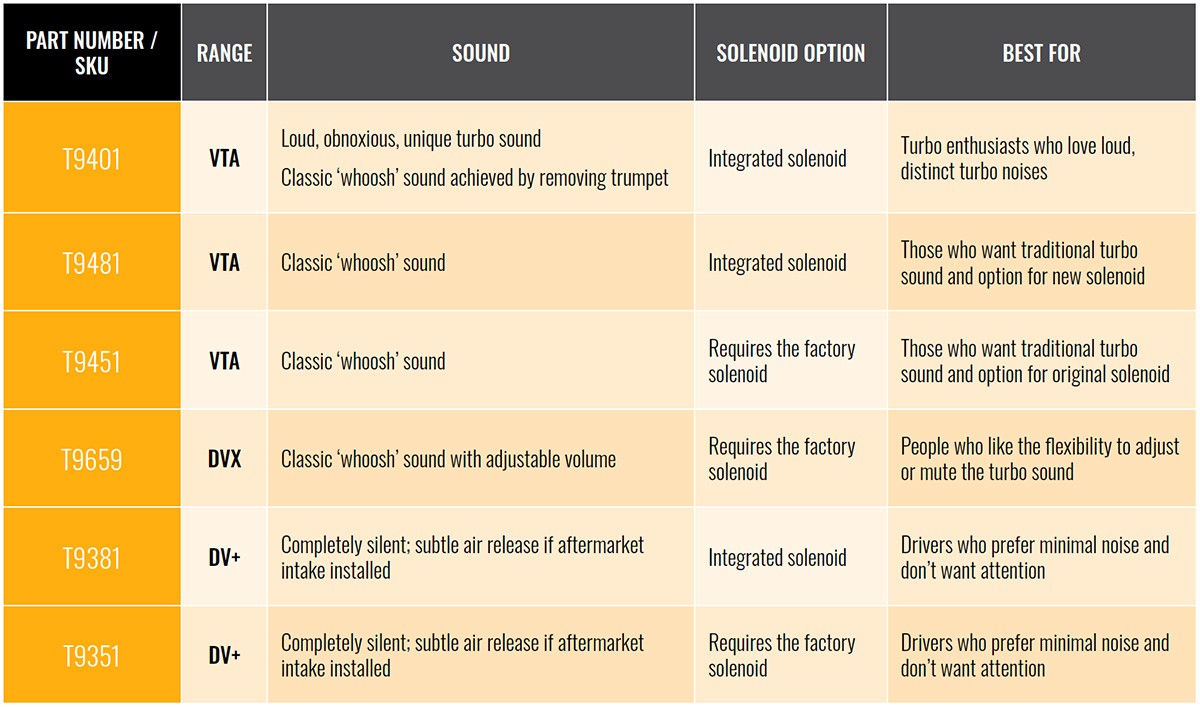

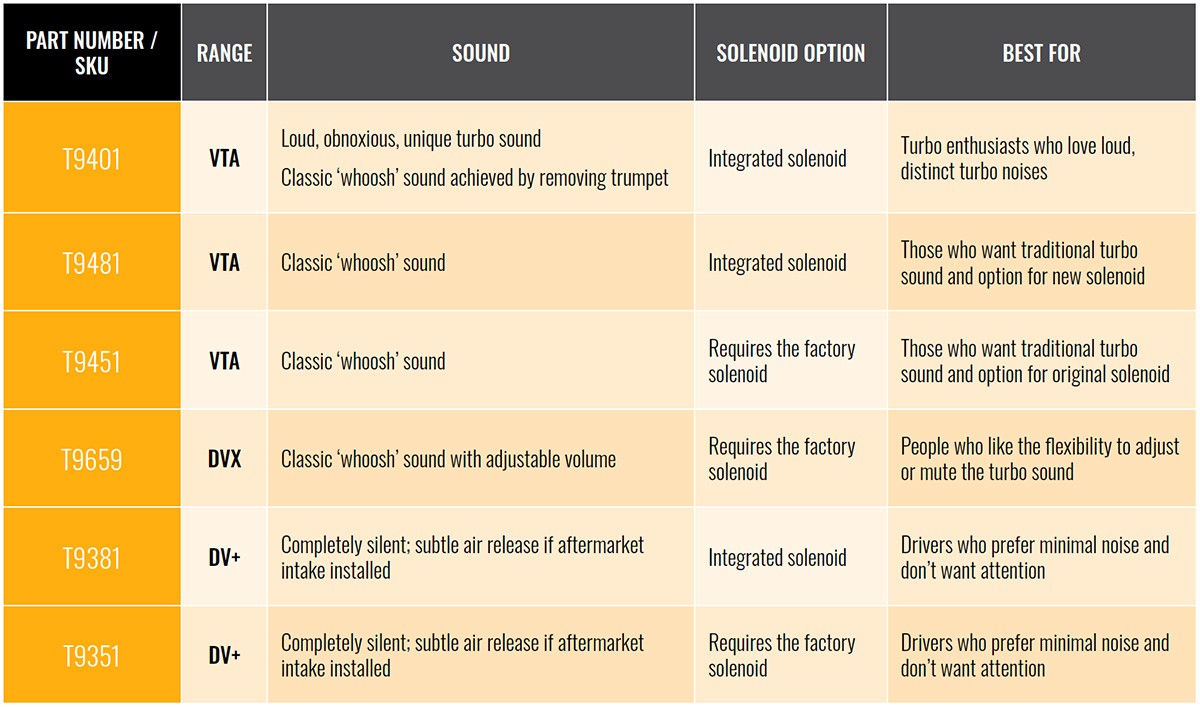

If you get a few different valve options for your vehicle, use the guide below to make sure you’re choosing the right one for your needs:

VTA Performance Blow Off Valve Range

The VTA is a high-performance blow-off valve solution for modern turbo vehicles fitted with an electronic factory diverter valve, offering better performance, reliability, and a great blow-off sound!

Release the Sounds!

We could tell you about the performance, reliability, and boost holding benefits of the VTA range, but let’s face it – you’re here for the sound, right?

By blasting the vented air out to atmosphere, the valves in the VTA family give your ride that signature blow-off sound when you lift off the throttle.

Uncompromised throttle response

Modern OEM electronic diverter valves might be faster than pneumatic types, but they are binary in operation – open or shut. What they gain in operational speed, they lose in throttle response. The VTA adapts the method of operation of the factory diverter system to give you the best of both worlds.

Pilot Operation – the patented design of the VTA means the piston is not directly connected to the solenoid, so it can open and shut progressively. This operation method leads to improved throttle response and drivability, because the VTA is more “discerning” about how much air it vents when triggered by the ECU – it only vents the amount of air necessary to eliminate pressure spikes that cause compressor surge, where the factory diverter opens fully whether it needs to or not.

When you close the throttle during spirited driving, the VTA opens to prevent compressor surge and protect the turbo. When the pressure has dropped sufficiently, the piston begins closing to preserve a small amount of boost in the intercooler for as long as possible. This helps the turbo return to peak boost faster when you re-open the throttle. We call this the

Turbo Management System (TMS) benefit.

Lightning-fast operation – vehicle manufacturers use an electronic diverter valve because they respond faster than pneumatic valves. Well, the VTA is faster again! No other valve on the market comes close to matching the VTA opening and closing speeds.

Hold my boost and watch this…

Your turbo works hard to create boost, so why make it work harder than it needs to? A GFB VTA ensures that all your hard-earned boost makes it to the engine.

Unsurprisingly, the moulded plastic valve components in the factory electronic diverter valve don’t seal that well. A boost leak from the factory diverter valve will cause the ECU to drive the turbo harder to compensate for the loss, resulting in higher turbo RPM, more exhaust backpressure, and hotter compressor outlet temperatures. So even though your tune might still hit target boost, a diverter leak means the turbo is more stressed, and the engine makes less power.

The VTA replaces the factory diverter’s loose-fitting plastic valve with precision CNC machined metal components and a durable elastomer piston seal. Because the VTA design uses boost pressure to force the piston shut, it doesn’t matter how much boost you throw at it – a VTA won’t fail, leak, or blow open.