Love it or hate it, the Subaru WRX can only be described as iconic. The basic recipe has remained the same for almost 30 years, and on one hand you could say that recipe is showing its age, but on the other hand it is a formula that obviously works – all-wheel drive, flat four turbocharged engine, excellent bang-for-buck, and a practical daily driver. What’s not to love?

Subaru 2022 WRX Features Electronic Diverter Valve

GFB can credit its origins directly to the WRX, as the excitement and possibility that a car like this offered in the late 1990’s was the reason we started making performance turbo products.

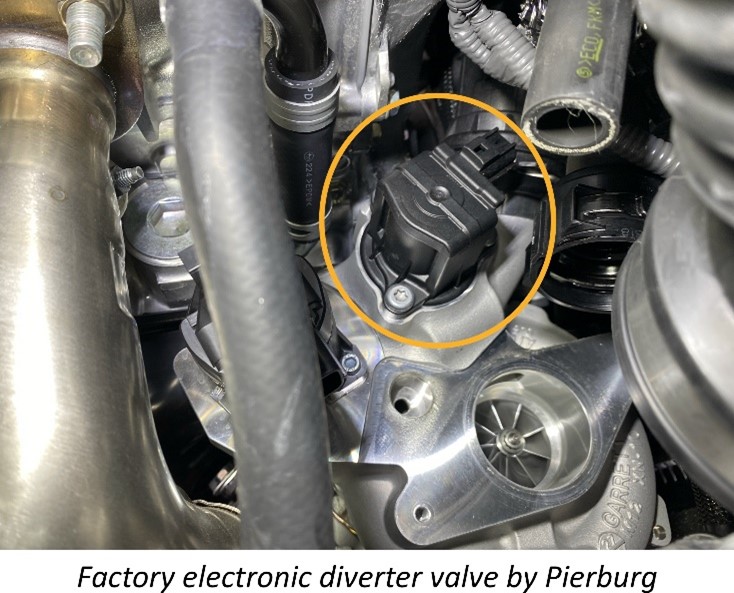

For almost 25 years we’ve offered a range of blow off and bypass valves for the WRX, and now, in the 2022 model we’ve seen the first significant change to the factory-fitted bypass/diverter valve, as it is now electronically controlled by the ECU.

Electronic diverter valves are not new, not even close. They first appeared in the Mk5 Golf GTI back in 2006, and before that Audi and VW were using a hybrid system where the regular pneumatic diverter valve was electronically controlled by a solenoid in the vacuum hose.

It is interesting that European manufacturers have been almost exclusively using electronic diverter valves for many years, and Japanese manufactures have (until now) been using traditional pneumatically controlled diverter valves, whilst the rest of the world has a foot in both camps.

Some manufactures have even experimented with deleting the diverter entirely. The first-generation Mercedes A45 was launched without a diverter valve, but the first facelift saw the re-introduction of a diverter valve. Audi and VW also dabbled, launching the 1.2 and 1.4TSI engines in 2014 without a diverter valve, but to date have not carried this over to other engines in their range. So far only BMW appears to be committed to deleting the diverter valve.

So we can conclude that the majority of OEMs are still seeing a need for a bypass valve, particularly on engines that run higher boost pressure. If it were possible to remove it without consequence, diverter valves would have been redundant years ago.

What’s so good about electronic diverter valves?

The factory electronic diverter valve is slowly but surely taking over from traditional pneumatic diverter valves, so clearly the OEMs see a benefit for making the switch.

The first benefit is packaging. By mounting it directly on the turbo compressor, you eliminate the associated hoses which saves cost, space, and also potential leaks from those hoses as they age.

When it comes to operation, electronic control offers more flexibility and response speed. Since the ECU is controlling both the throttle and the diverter valve, it can time the diverter to open the instant the throttle begins to close, unlike a pneumatic valve that needs a significant manifold pressure drop before the valve can start to open. This helps reduce pressure spikes on throttle closure to more effectively manage compressor surge.

We’ve also seen Ford use the diverter valve to “de-pressurise” the turbo compressor during cruise to improve economy and reduce load on the turbo when power is not needed.

What’s not so good?

We agree that electronic diverter valves offer a significant speed advantage that helps eliminate pressure spikes which is beneficial for the turbo – the ability of the ECU to control the diverter and the throttle in harmony is an important improvement. However, when it comes to performance and reliability, it has been our experience that factory electronic diverter valves are a backwards step, and here’s why:

Plastic parts:

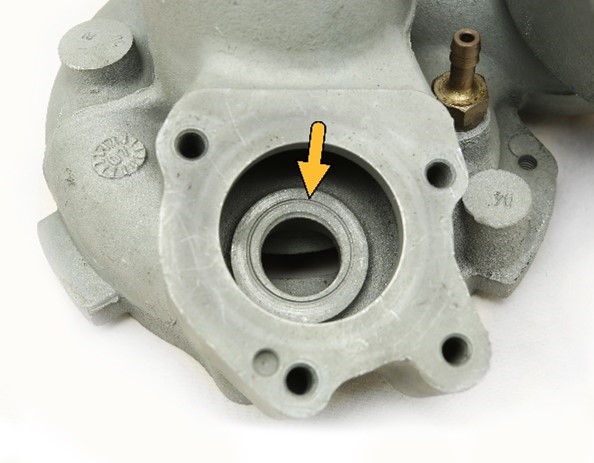

Modern plastics are better than they used to be, but even so there’s just no way to seal a moulded plastic piston properly. They do use a piston seal, but this is also made of plastic and because this type of valve will not operate reliably with friction from an “engaged” seal, the fit is a very loose and leaks a reasonable amount of air. You can see the gap between the blue seal and the piston in the picture opposite.

It is also common for the sharp leading edge of the piston to bite into and damage the seat face on the turbo. Even after as little as 15,000km, a shallow impression can be seen. After 75,000km it is not uncommon to see a significant groove worn into the turbo seat by the piston. Eventually this will lead to further boost leaks that cannot be resolved by replacing the diverter valve.

Throttle response:

The single biggest issue with factory electronic diverter valves is that they are digital in operation – open or closed, nothing in between. The ECU triggers the diverter valve to open the instant the throttle begins to close and holds it open for about 2 seconds (unless you re-open the throttle before then). It does not consider the boost pressure, engine load, or RPM. So even if you only partially lift the throttle, the factory valve opens fully.

During spirited driving conditions it is common to make lots of small throttle adjustments to balance the car when cornering, and the operation of the factory diverter makes this task more difficult by creating a very non-linear boost response.

Furthermore, during a gearshift on a manual vehicle, the factory diverter will remain wide open for the entire duration of the gearshift and will drop the intercooler pressure to zero. When you grab the next gear, the turbo must start building boost from scratch.

What’s GFB’s solution?

Here’s the great news – because the factory Pierburg valve on the 2022 WRX has been around in one form or another for many years, so has our solution, and it has a long history of success (check out our DV+ launch video from 2013)!

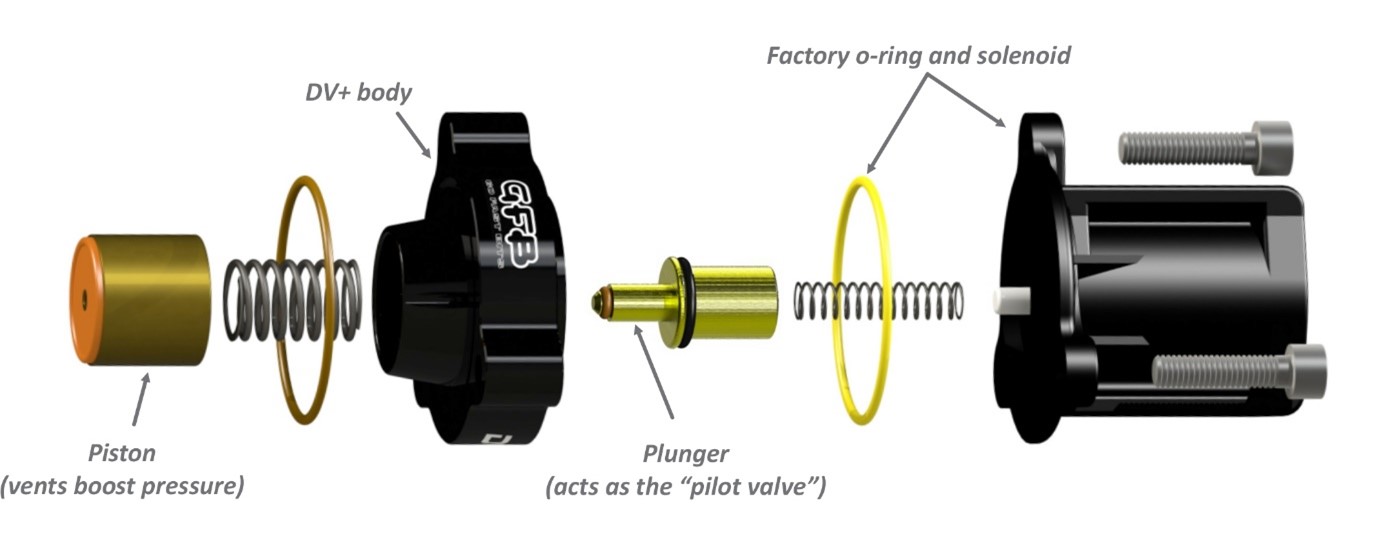

The GFB DV+ is an innovative patented solution that solves all the shortcomings of the factory electronic diverter valve, replacing the plastic valve assembly with precision CNC machined metal components to ensure reliable operation and no boost leaks (backed by a lifetime warranty), and changes the operation method so it can open and close progressively (whilst retaining electronic control) to ensure the best possible throttle response from your turbo.

Here’s how it works:

In the factory electronic diverter valve the solenoid is connected directly to the valve. The spring pushes the valve closed, and the solenoid coil pulls it open, which is why it can only ever be open or shut.

The DV+ however uses a “pilot actuation” system, where the solenoid is used to control the opening and closing of a small “pilot valve”. Because of this, the stroke of the solenoid is reduced from 5mm in the factory valve to less than 1mm in the DV+, resulting in faster operation.

When the pilot valve is closed, pressure on the front and back of the piston is equal, courtesy of the small transfer hole in the face of the piston. However, because the area on the front of the piston is smaller than the area at the back, there is a force imbalance that pushes the piston onto the seat. The more boost, the harder the piston is forced closed.

When the ECU triggers the diverter, the solenoid opens the pilot valve which relieves the pressure behind the piston and allows the boost pressure to blow it open. However, once the necessary pressure has been relieved, the spring will start to push the piston closed again, even if the ECU is still holding the pilot valve open.

This is how the DV+ can open and close progressively in response to the existing boost pressure and the factory valve can’t. The DV+ opens when the ECU tells it to, but ONLY if there is boost that needs to be vented.